Today, in a conversation with Martin Mohrmann for the Lübeck ZWISCHENZEILEN, I take a look behind the facade of his Mohrmann belt manufactory and get to know a dedicated entrepreneur who manufactures unique accessories in the heart of Lübeck’s Old Town at Fleischhauerstraße 52 and who, at the same time, cares about the future of our planet.

Fashion fades – style remains

Belts hang in every closet. As a fashion statement, they have been known since the Bronze Age. At that time, a self-respecting woman wore elaborately crafted belts studded with bronze discs. In the Middle Ages belts were worn for quite practical considerations. For example, because weapons, quivers or the cartridge bag had to be transported. The medieval housewife attached to the belt knife, keys and bag.

Of course, Lübeck was no different: during excavations in the merchants’ quarter around Alfstraße and Fischstraße, shoes, belts and bags were discovered. In addition, metal costume accessories of the Middle Ages and the early modern period such as buttons, buckles and belt components. On the upper part of the Schrangen was the meat market, further down the camp, where convicts were imprisoned. In the remains of a public toilet found during excavations there was a magnificent belt made of silk from the 14th century.

Today, belts serve purely to hold the pants, but much more as a fashion accessory that expresses a sense of style. Giving your own look a noble finish and accentuating the silhouette: Martin Mohrmann and his team have been helping to achieve this since 2003.

High quality unique items FROM the belt manufactory

Over the past decades, Martin Mohrmann has acquired impressive expertise in the manufacture of high-quality leather belts. In his younger years, he sold leather goods at markets and found that leather belts were most in demand. He ran a small workshop in Fleischhauerstraße and took the opportunity to open a store in the winding building when the premises facing the street became available. This was the starting point for a unique success story.

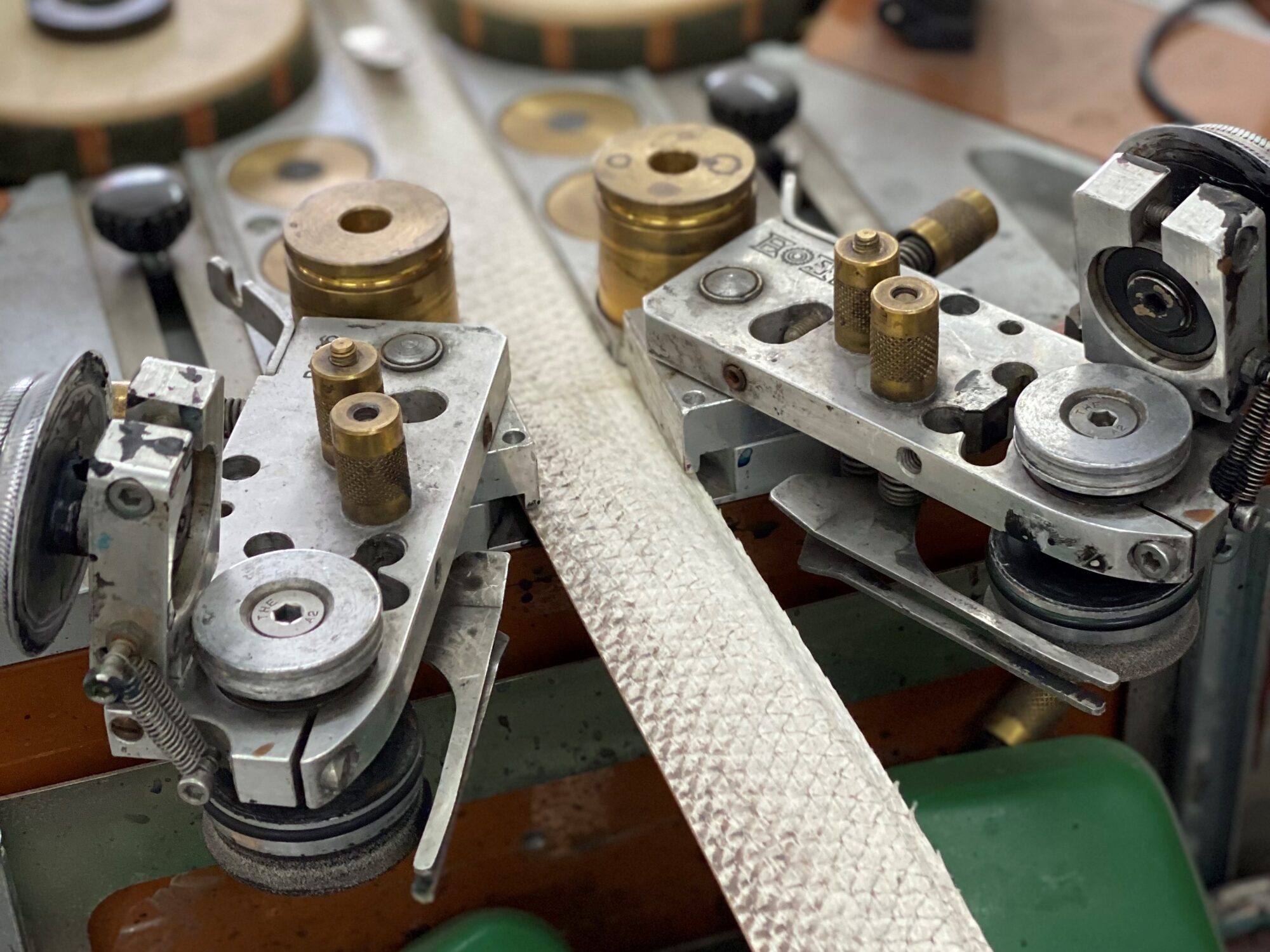

The manufactory has been significantly expanded since 2003 and the owner invested in the latest technology. The selection of high-quality leathers ranges from cowhide, which is part of every belt from Mohrmann, to exclusive materials such as ostrich foot leather to skins of crocodiles and alligators. While he leads me up and down the stairs through the manufactory, Martin Mohrmann tells me that each leather places very specific demands on the belt maker. In his manufactory the leather is cut and glued, dyed and polished. Edges are smoothed in a complex process in a special machine from Italy, but also by hand.

the Holsten Gate as a belt buckle

The store smells so wonderfully of leather. Here only the belts from the Mohrmann production are on offer. 4 years ago Martin Mohrmann started making buckles from recycled pewter. He designs the models required for this in a 3-D printer. The buckles also go through a multi-stage manufacturing process until the blanks become magnificent buckles that can be purchased in this quality only at Mohrmann Gürtelmanufaktur. Of course, the Holsten Gate and the striking Lübeck silhouette as a belt buckle may not be missing. However, the assortment also includes plain buckles and maritime designs such as seagulls, anchors and walrus.

Acting sustainably

In recent years, Martin Mohrmann has placed increasing emphasis on producing as sustainably as possible. For example, he no longer sources the ostrich foot leather from South Africa, but from ostrich farms in Germany. The ostriches are not bred for leather production, so the ostrich feet are virtually a by-product from which the high-quality leather belts are made. On the company website, a CO2 calculator can be used to check which emissions are released in the production process of a belt. Interested customers can also access background knowledge on the subject of sustainability in leather production and processing.

Martin Mohrmann is also committed to environmental and climate protection projects beyond his own company. His latest initiative is the purchase of a Muli-Cycle cargo bike for emission-free transport in Lübeck and the surrounding area. You can read more about this shortly at https://veload.de/.

A belt from the manufactory Mohrmann lasts for many years. An investment in quality that pays off. And if a belt buckle should no longer please, there is always the possibility of melting it down and opting for a new design.